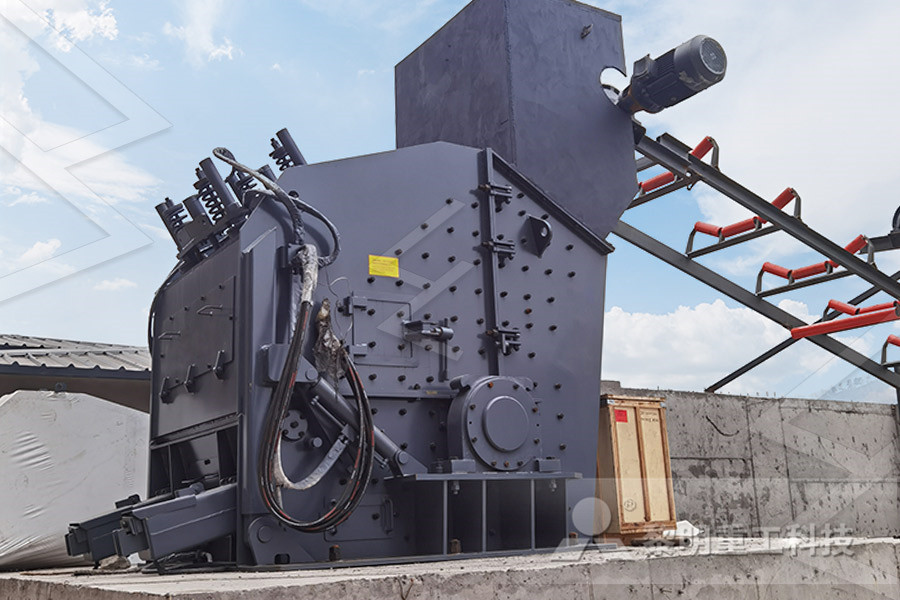

Durable Use Types Of Jaw Crusher

2023-04-16T22:04:49+00:00

Jaw Crusher an overview ScienceDirect Topics

The main crushers’ types are: • Jaw crusher: The material is crushed between a fixed jaw and a mobile jaw The feed is subjected to repeated pressure as it passes downwards and is progressively reduced in size until it is small enough to pass out of the crushing chamber2016年1月1日 Designs of different types of jaw crushers such as Blake, Dodge with single and double toggles used for initial comminution of minerals, as received from mines, are Jaw Crusher ScienceDirect2022年6月8日 Double toggle movement jaw crushers like the Blake style (named for the inventor of the first successful mechanical jaw crusher, How Does a Jaw Crusher Work Jaw Crusher Kemper

Jaw crusher: types, principle and applications ResearchGate

Jaw Crusher can be used in mining, metallurgical industry, construction, road and railway building, chemistry etc FEATURES OF JAW CRUSHER • Simple structure easy 2019年5月30日 What are the Different Types of Jaw Crushers? Jaw crushers have been around for nearly 200 years and are one of the most “historic” crusher types Because of this, jaw crushers have5 Common Questions about Jaw Crushers AnsweredThere are two main types of jaw crushers: jaw crushers that use stationary jaw plates and jaw crushers that use movable jaw plates While both types of jaw crushers work Jaw Crusher: What Is It How Does It Work? Vykin Machinery

Performance optimization of jawtype rock crushing machine

2019年12月11日 The machine performed exceptionally well with an efficiency of 95% and is relatively durable compared to high grade imported rock crushing machine Keywords: 2020年6月1日 Coarse aggregates for unbound use are often produced using a single crushing stage in a jaw crusher, as opposed to concrete or asphalt aggregates, where Influence of jaw crusher parameters on the quality of 2023年7月10日 Mobile jaw crusher: High mobility determines that it is suitable for frequent conversion of crushing sites (like road construction, urban construction waste disposal, etc)Thus, its price is higher than Characteristics and Comparison of Four Types of

primary jaw crusher design LinkedIn

2023年3月29日 Jaw plate design: The design of the jaw plates can also have an impact on the performance of the crusher Different designs may be used depending on the type of material being crushed, the Jaw crusher is a heavyduty which crushing the hard rock Therefore, the jaw crusher parts need to be very hard and durable In particular, the two components of the jaw crusher work, the fixed jaw, and the movable 5 Types Of Stone Crushers Application and There are lots of different kinds of crushers from jaw crushers to impactors and cone crushers Crushing is an versatile process and the kind of crusher you need depends on the 'stage' of crushing The three main stages of crushing are primary, secondary, and tertiary all of which have their own unique benefitsTypes of Crushers: What You Need to Know Machinery Partner

Concrete Crusher Its Types Specifications

2023年11月3日 Impressive durable equipment’s of crushers can make little pieces into the reusable aggregates and gravels onsite component of the building structure Types of Concrete Crushers A) Concrete Crusher of Jaw The most uses of primary jaw crushers using the same technology for a nut cutterThe capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation The capacity is primarily a function of: 1 crusher design characteristics such as width and depth of the crushing chamber, 2 Jaw Crusher an overview ScienceDirect Topics2020年12月17日 Jaw crushers can be divided into two basic types, single and double toggle In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher Shaft rotation, along with the toggle plate, causes a compressive action A double toggle crusher has two shafts and two toggle plates The first shaft is a pivoting shaft on the top Crushing 101 – Different types of crushers for distinctive needs

What Are Jaw Crushers and How Do They Work? Oreflow

March 28, 2019 / in News A jaw crusher is a large piece of equipment that’s used in mine and ore processing plants to crush rocks The equipment was first introduced back in 1858 by inventor Eli Whitey Black who primarily developed machinery used for crushing stone From there, jaw crushers have seen plenty of action in the pit and quarry 2015年4月3日 There are several types of crushers which are used in various industries These are given below Jaw crusher Jaw crusher is used as primary crusher It uses compressive force for breaking the material This mechanical pressure is achieved by the two jaws of the crusher Reduction ratio is usually 6:1Crushers and Their Types – IspatGuru295445 340540 370560 400585 150 225 Rocktech Engineers is one of the best Jaw Crusher Exporters, Suppliers, Manufacturers in India NOTE: Due to the difference of rocks and the size percentage, distribution and the practical capacity will be different Jaw Crusher Exporters Manufacturers in Mumbai, IndiaJaw Crusher Exporters Manufacturers in India Rocktech Engineers

Crushing and Screening Handbook AusIMM

the crusher and scalp out fi nes Primary gyratory crushers – ideally suited to all highcapacity primary hard rock crushing applications Jaw crushers – we have more installed jaw crushers than anyone in the world The leading choice due to their high reduction ratio and heavy duty design Cone crushers – capacities available to suit allAnd it is widely used in metallurgy, building, hydropower, transportation, chemical industry, etc When used with jaw crusher, it can be used as secondary, tertiary or quaternary crushing Generally speaking, the standard type of Symons cone crusher is applied to medium crushing The medium type is applied to fine crushingCrusher Wikipedia2022年10月24日 Disadvantages of jaw crusher: The jaw crusher cannot complete multidimensional crushing If the materials to be crushed are diverse, the traditional crushing process cannot completely dissociate Advantages and Disadvantages of Jaw Crusher Machine

Advantages of a Jaw Crusher Living Well Center

2022年6月6日 They can be operated easily and are durable However, the size of the feed opening and particle size capacity of a jaw crusher depend on the size of the jaw plates A typical jaw crusher can process 7080% of its feed opening, but this may vary from manufacturer to manufacturer Moreover, the material used for the jaws can be a variety 2023年2月28日 Jaw crushers are one of the most commonly used crushing machines in the mining and quarrying industryThey are typically used as primary crushers to reduce large rocks, ores, and minerals into smaller, more manageable sizes The design of a jaw crusher plays a crucial role in its operation and efficiency, and this article will explore The Importance of Jaw Crusher Design Features in Crushing 2023年3月16日 A jaw crusher is used to reduce the size of many different types of materials in many applications The jaw crusher uses a stationary jaw plate and a moving jaw plate to create a unique “V” shapeWhat is the use of a jaw crusher? LinkedIn

Jaw crusher types and applications News of Joyal Crusher

2021年6月24日 In terms of medium and fine crushing, jaw crushers are mostly selected for small output Otherwise, choose a cone crusher Feeding mouth width greater than 600mm is a largescale crusher, feeding mouth width 500600mm is a mediumsized crusher, and feeding mouth width is less than 500mm is a small crusher The jaw crusher has a 2019年4月18日 Abstract and Figures This study covers the investigation of rock crushability using laboratoryscale cone and jaw crushers for five types of hardrocks For this purpose, physicomechanical (PDF) An experimental investigation on rock crushability using jaw 2021年3月25日 Hammermills can be used as a primary crusher in many types of aggregate and industrial applications, including limestone, marble, shale, gypsum, phosphate, bauxite, aluminum dross, uranium, cryolite, clinkers, quicklime, petroleum coke, coal and more Using a combination of impact, shear and attrition reduction methods, McLanahan What Type of Crusher Is Best for Primary Crushing?

Jaw Crusher Primary Crusher in Mining Aggregate JXSC Mine

JXSC jaw type rock crusher is usually used as a primary crusher and secondary crusher to reduce the size of mediumhard materials to smaller physical size Jaw rock crushers are capable of working with the mobile crushing station, underground crushing because of its related small volume Capacity: 11120TPHMechanical Crushing and Grinding Oleg D Neikov, in Handbook of NonFerrous Metal Powders, 2009 Crushers Crushers are widely used as a primary stage to produce the particulate product finer than about 50–100 mm in size They are classified as jaw, gyratory and cone crushers based on compression, cutter mill based on shear and hammer Crusher an overview ScienceDirect Topics2023年2月27日 A jaw crusher is a machine that breaks down big rocks into smaller ones It has two jaws, one fixed and the other moving, that work together to crush the material The fixed jaw is mounted on a frame and cannot move, while the moving jaw is connected to an eccentric shaft Jaw crushers are used extensively in the mining, quarrying, and What Is a Jaw Crusher? Sandrock Mining

Jaw Crusher Mineral Processing

Introduction: Jaw crusher is a robust size reduction equipment designed to reduce large solid materials into smaller particles, widely used in the quarrying, metallurgical and allied industries Jaw crusher is one of the This would mean they would need regular maintenance and replacement If you want to crush lots of hard rock you would need a heavyduty machine such as the Omega J1065T jaw crusher or Rockster R900 impact crusher Most jaw crushers will crush soft rock quickly and easily The ARK 704 jaw crusher would be a perfectHow to Crush Stone: A Simple Guide Machinery Partner241 Types of Crushers 2411 Jaw Crusher Jaw crushers operate by squeezing a rock particle placed between a fixed and a moving plate (jaw) Both plates could be flat or the fixed plate flat and the moving convex The moving plate is the one which applies the force of impact particles held on the stationery plate There are two main types Design of a crushing system that improves the crushing efficiency

What mineral types are good for a jaw crusher? LinkedIn

2023年2月16日 2 Basalt: This is another hard, igneous rock that is commonly used in construction and building materials It is similar to granite in terms of durability and is also suitable for jaw crushers 3 Contribute to chengxinjia/ development by creating an account on GitHub/ high quality durable use jaw crusher150x750md at 2020年3月19日 Best suited for secondary crushing applications, cone crushers are designed to crush presized materials, usually 100mm, 150mm or 200mm, depending on the size of the crusher Cone crushers can form finished products down to 12mm or less Like the jaw crusher, the cone crusher provides a relatively low cost crushing solution, but Selecting the right crusher for your operations Quarry

difference between roller crusher and jaw crusher LinkedIn

2023年3月15日 A jaw crusher is a machine that uses two plates, or jaws, to crush materials The jaws are positioned in a "V" shape, with one jaw moving back and forth to crush materials against the other fixed jaw2023年9月8日 Disadvantages of Cone Crusher: 1 Higher Initial Cost: Cone crushers often have a higher upfront cost compared to jaw crushers and impact crushers This can be a significant factor for smaller Advantages and disadvantages of jaw crusher and cone crusherThe different types of crushers Jaw Crusher The composition of a jaw crusher is characterized by its two jaw plates, one fixed and the other moving, both oriented to create a Vshaped chamber through which What Are Crushers? Eagle Crusher

McLanahan Types of Crushers in Sampling

2021年1月29日 How a Jaw Crusher works Reduction Ratio of Sampling Jaw Crushers Jaw Crushers typically have a crushing ratio of 6:1, though there are a number of high efficiency Jaw Crushers available that can 2021年2月18日 Jaw crushers typically use the principles of compression and friction to break materials down They’re extremely powerful equipment that should be used with the utmost care Jaw crushers are so powerful What Is a Jaw Crusher? Here's How It Works2017年2月6日 Jaw crusher commonly known as jaw broken, also known as tiger’s mouth Is the emergence of earlier crushing equipment, with durable, excellent performance, easy maintenance, flexible adjustment The Advantages and Disadvantages of Jaw Plate Material of

Performance optimization of jawtype rock crushing machine

2021年6月22日 The results show that an external diameter/offset ratio within the average of 10:1 can be considered for the offset calculation of a jawtype crusher shaft The outcome of the result was used to redesign and develop a prototype crushing machine with better output crushing pressure of 131×10 5 kN/m 2 and capable of crushing 425–569 Compared with traditional jaw crusher, JC series jaw crushers pays more attention on details in the process of design and manufacture It uses highstrength materials, advanced manufacturing technology, which contributes to the stronger structure, higher reliability, larger crushing ratio, higher productivity, lower costJaw Crusher, Jaw Crusher price, jaw crusher manufacturer2016年2月28日 Large receiving opening per dollar of investment Shape of receiving opening favourable for blocky feed This, plus point 1, give the jaw a definite advantage over the gyratory, except in the very large sizes, for handling rock of massive formation The jaw crusher is more easily adjusted, to compensate for wear of linersGyratory VS Jaw Crushers: Advantages Disadvantages 911

February 2018, Volume 5, Issue 2 JETIR (ISSN 2349 5162) DESIGN

Different Types of Jaw Crusher: Jaw crusher can be divided into two according to the amplitude of motion of the moving face The different types of Jaw Crushers are Blake Type Jaw Crusher and Dodge Type Jaw Crusher II LITERATURE REVIEW Shyam SundarV has published a paper on "OPTIMUM DESIGN AND ANALYSIS OF SINGLE The jaw crusher is suitable for crushing various ores or rocks with a compressive strength limit below 250 MPa Widely apply for mining, cement and concrete industries It is mainly used as coarse crusher and medium crusher in mines, building materials and infrastructure The jaw cement crusher produced by AGICO Cement has the Jaw Crusher For Sale Jaw Crusher Jaw Crusher Manufacturer1) Obtaining the size or surface area required for the use of the ore or material 2) Allowing ease of transportation and storage 3) Separating the different minerals contained within the ore and to release them from one another 4)What Is A Jaw Crusher MEKA

Characteristics and Comparison of Four Types of

2023年7月10日 Mobile jaw crusher: High mobility determines that it is suitable for frequent conversion of crushing sites (like road construction, urban construction waste disposal, etc)Thus, its price is higher than 2023年3月29日 Jaw plate design: The design of the jaw plates can also have an impact on the performance of the crusher Different designs may be used depending on the type of material being crushed, the primary jaw crusher design LinkedInJaw crusher is a heavyduty which crushing the hard rock Therefore, the jaw crusher parts need to be very hard and durable In particular, the two components of the jaw crusher work, the fixed jaw, and the movable 5 Types Of Stone Crushers Application and

Types of Crushers: What You Need to Know Machinery Partner

There are lots of different kinds of crushers from jaw crushers to impactors and cone crushers Crushing is an versatile process and the kind of crusher you need depends on the 'stage' of crushing The three main stages of crushing are primary, secondary, and tertiary all of which have their own unique benefits2023年11月3日 Impressive durable equipment’s of crushers can make little pieces into the reusable aggregates and gravels onsite component of the building structure Types of Concrete Crushers A) Concrete Crusher of Jaw The most uses of primary jaw crushers using the same technology for a nut cutterConcrete Crusher Its Types SpecificationsThe capacity of jaw crushers is a measure of the mass or volume of crushed material produced in unit time of operation The capacity is primarily a function of: 1 crusher design characteristics such as width and depth of the crushing chamber, 2 Jaw Crusher an overview ScienceDirect Topics

Crushing 101 – Different types of crushers for distinctive needs

2020年12月17日 Jaw crushers can be divided into two basic types, single and double toggle In the single toggle jaw crusher, an eccentric shaft is on the top of the crusher Shaft rotation, along with the toggle plate, causes a compressive action A double toggle crusher has two shafts and two toggle plates The first shaft is a pivoting shaft on the top March 28, 2019 / in News A jaw crusher is a large piece of equipment that’s used in mine and ore processing plants to crush rocks The equipment was first introduced back in 1858 by inventor Eli Whitey Black who primarily developed machinery used for crushing stone From there, jaw crushers have seen plenty of action in the pit and quarry What Are Jaw Crushers and How Do They Work? Oreflow2015年4月3日 There are several types of crushers which are used in various industries These are given below Jaw crusher Jaw crusher is used as primary crusher It uses compressive force for breaking the material This mechanical pressure is achieved by the two jaws of the crusher Reduction ratio is usually 6:1Crushers and Their Types – IspatGuru

Jaw Crusher Exporters Manufacturers in India Rocktech Engineers

295445 340540 370560 400585 150 225 Rocktech Engineers is one of the best Jaw Crusher Exporters, Suppliers, Manufacturers in India NOTE: Due to the difference of rocks and the size percentage, distribution and the practical capacity will be different Jaw Crusher Exporters Manufacturers in Mumbai, India