optimisation of ball charge cement mill

2023-12-17T07:12:53+00:00

OPTIMIZATION OF CEMENT GRINDING OPERATION IN BALL MILLS

Optimization of the Cement Ball Mill Operation Optimization addresses the grinding process, maintenance and product quality The objective is to achieve a more efficient 2004年12月10日 The ball charge filling ratio and the L/D ratio are influencing the specific power consumption and the throughput simultaneously Furthermore, the absolute Optimization of continuous ball mills used for finishgrinding of 2004年12月10日 Optimization of continuous ball mills used for finishgrinding of cement by varying the L/D ratio, ball charge filling ratio, ball size and residence time Optimization of continuous ball mills used for finish

Ball charge optimization INFINITY FOR CEMENT EQUIPMENT

Previous Post Next Post Contents1 Ball charge optimization2 1 How to use the BP21 2 Description of the main indicators used in this BP2101 The residue on 2mm/4mm before partition wall2102 Material filling level and ball charge expansion211 Cement mill specific power 1st compartment 212 Raw mill specific power 1st compartment Ball 2004年12月10日 The labmill (∅ 075×045 m, ball charge filling ratio 10%, relative mill speed 088) were fed with clinker meal with a Blaine surface area of 2700 cm 2 /g The massspecific power consumption for the grinding to finenesses of 3000, 4000 and 5000 cm 2 /g were determinedOptimization of continuous ball mills used for finishgrinding of 1992年3月1日 Abstract and Figures The combination of a grinding circuit simulator with a model of ball wear in a grinding mill leads to a method to calculate, with a preselected accuracy, the makeup ball Optimization of the makeup ball charge in a

Optimisation of the ball charge in mills for cement grinding

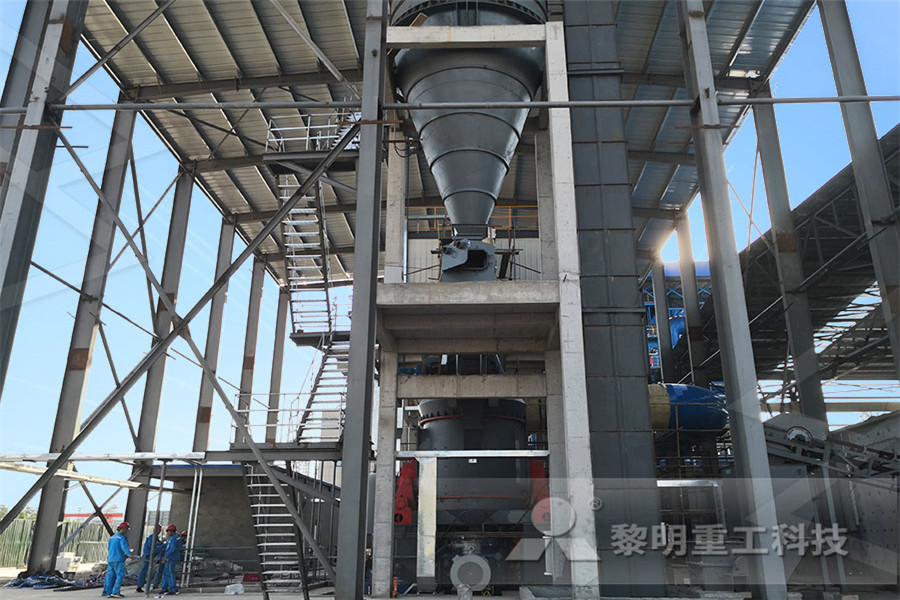

2009年11月1日 The development of Loesche vertical roller mills for large capacity grinding is discussed With 3+3 technology, the company is prepared to replace 2 to 3 ball mills in cement grinding plants with 2020年5月1日 The primary ball charge pattern and the design ball charge pattern that is introduced by KHD Company (Cement ball mill’s manufacture Company) are presented in Table 6 It can be observed in this table that the amount of current ball charge is about 14% less than the amount of design ball charge, so it could reduce the CBM’s efficiencyEnergy and exergy analyses for a cement ball mill of a new 2017年10月25日 Ball Mill Breakage Efficiency Consider a ball mill circuit processing material of a given feed size and at a given throughput rate to a target product size, the latter which once again distinguishes the “fines” from the “coarse” material The production rate of fines or new product size material can be calculated from the circuit feed How to Improve Ball Mill Performance 911 Metallurgist

(PDF) Performance optimization of an industrial ball mill for

2017年1月1日 An increase of over 10% in mill throughput was achieved by removing the ball scats from a single stage SAG mill These scats are non spherical ball fragments resulting from uneven wear of balls 2015年4月1日 1 Introduction Airswept raw meal ball mills introduced by the cement mill manufacturers ® (Smidth, 2002), Polysius ® (Polysius, 2002) and KHD Humboldt Wedag® are the most commonly used onesKHD Humboldt Wedag® manufactured fully airswept raw meal mills which have two compartments used for drying and grinding Optimization of a fully airswept dry grinding cement raw meal ball 2018年12月17日 The nearby cement plant operates with 20 mins retention time for clinker grinding in the ball mill 70 Ton hold up Power consumption = kW = 75 x Gw x D05 = 75 x 163 x 3805 = 2383 kW (Check its correctness) (13) Grinding energy = 3035 kWh / Ton cement Here, Gw = ball charge, ( Ton ); and D = Effective mill diameter, ( m )Ball Mill Optimization PDF SlideShare

Ball Charge and Grinding Efficiency Grinding Classification

Also with low ball charge slurry pool will reduce grinding efficiency Beside lower ball charge will increase P80 of ball mill because of less number of impacts but mean residence time will increase by lower ball charge because of more volume to occupy I think at last in this situation, power consumption will increase% at mill motor (ball mill 100%) % 100 83 57 57 Specel Energy consumption mill system kWh/t 39 32 27 26 % department (ball mill 100%) % 100 82 69 67 Figure 1 Shows a typical flowsheet for a ball mill installation Drying Coarse Grinding Fine Grinding Classification Ball Charge Management Grinding Ventilation and Cooling Operation and ControlThomas Holzinger, Holzinger Consulting, grinding system optimisation2019年12月2日 The ball charge typically occupies around 30%36% of the volume of the mill, Cement Mills Optimization The Quality Perspective Nohman Mahmud 4y Cement Finish Milling (Part 1: Introduction History)

Optimization of Continuous Ball Mills PDF Mill (Grinding)

Optimization of continuous ball mills used for finishgrinding During the last decade, semifinishgrinding plants have been used more and more for the energy efficient grinding of highquality cement In 1999, it was found that by decreasing the ball charge filling ratio it was possible to lower the specific energyCEMENT MILL OPTIMISATION CASE STUDY VK Batra*, D Bhaskara Rao** and Raju Goyal*** Holtec Consulting Private Ltd, New Delhi The mill is designed to handle a total ball charge of 3245 t at 100% loading with a percentage filling of PROCESS DIAGNOSTIC STUDIES FOR CEMENT MILL OPTIMISATION 2004年12月1日 During the last decade, semifinishgrinding plants have been used more and more for the energy efficient grinding of highquality cement In 1999, it was found that by decreasing the ball charge Optimization of continuous ball mills used for finishgrinding of

Ball charges calculators

It gives also a rough interpretation of the ball charge efficiency: Ball top size (bond formula): calculation of the top size grinding media (balls or cylpebs): Modification of the Ball Charge: This calculator analyses the granulometry of the material inside the mill and proposes a modification of the ball charge in order to improve the mill efficiency:2016年1月20日 Ball mill optimization Dhaka, Bangladesh 21 March 2010 1 Introduction MrPeramasWajananawat Experience: 13 Years (2 y in engineering,11 y in production) Mill charge optimization To Cement Silo Cement Mill Clinker Gypsum Limestone 8 Page 9 What is function of mill? 9 MBall Mill Optimization [PDF Document]Cement mill 812 kWh/t Raw mill 40 – 45 % of total mill power consumption Diaphragm slot openings are : 68 mm in the first compartment 810 mm in the second compartment Prerequisites Mill feedsize Clinker and additives 95% passing 25 mm; 100 % passing 50 mm Raw material 95% passing 30 mm; 100 % passing 50 mmPR GRI P0708 How To Optimise A Ball Charge PDF Mill

How to choose proper grinding media for your ball mill

2021年2月24日 Steel balls are one of the most widely used grinding media in cement ball mills, their diameters can range from 20mm to 120mm according to different grinding requirements In a cement ball mill, generally, φ50–100mm steel balls are used in the coarse grinding chamber, φ20–50mm steel balls are used in the fine grinding chamber 22016年10月5日 The energy consumption of the total grinding plant can be reduced by 20–30 % for cement clinker and 30–40 % for other raw materials The overall grinding circuit efficiency and stability are improved The maintenance cost of the ball mill is reduced as the lifetime of grinding media and partition grates is extended 25EnergyEfficient Technologies in Cement Grinding IntechOpen2016年9月10日 The effects of ball charge pattern, cement fineness and two additive materials (limestone and pozzolan) on the performance of the CBM unit and the quality of cement were investigated The first and second laws efficiency of the CBM increased (818% and 206%) and the electrical energy consumption of CBM unit decreased (365 Optimization of an industrial scale open circuit three

Cement Mills Optimization The Quality

2019年6月13日 Cement Mills Optimization The Quality Perspective (Heat Rise of Kiln Charge / Feed) 5 Common Problems of the Balls of Ball Mill in Working Conditions and SolutionsBall mill optimization Dhaka, Bangladesh 21 March 2010 1 Introduction MrPeramas Wajananawat Experience: 13 Years (2 y in engineering,11 y in production) Engineering department(PDF) Ball Mill Optimization DOKUMENTIPSBALL MILL OPERATION, INSPECTION OPTIMIZATION Jakarta, 1415 Juni 2012RBSTM PARAMETER OF QUALITY FINISH MILL(1) STRENGTHÆ clinker minerals: C3S , C2S +additive materials (trass LS) ; SIA 1 day : 125 kg/cm2 3 day : 220 kg/cm2 7 day : 280 kg/cm2 28 day : 380 kg/cm2 BLAINEÆ Classifier PCC : 3700 – 4200 cm2/g OPC : Ball Mill Operation, Inspection Optimization PDF Mill

Ball Mill Optimization PDF Mill (Grinding) Particle Size

Ball mill optimization Dhaka, Bangladesh 21 March 2010 Introduction MrPeramas Wajananawat Experience: 13 Years (2 y in engineering,11 y in production) Engineering department Siam Cement (Ta Luang) Siam Cement (Lampang) Kiln and Burning system Kiln system, Raw material grinding and Coal grinding Cement grinding and Packing 2019年12月2日 The ball charge typically occupies around 30%36% of the volume of the mill, Cement Mills Optimization The Quality Perspective Nohman Mahmud 4yCement Finish Milling (Part 1: Introduction History)Optimisation of the ball charge in mills for cement grinding First results have already shown the extensive potential for determining wellfounded rul [ protected] WhatsApp:+86 shows the plots required to complete the optimization The ball mill, liners andcharge cement mill

Ball Mill Optimization PDF Mill (Grinding) Mathematical

Ball Mill Optimization Free download as PDF File (pdf), Text File (txt) A 15 mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill is designed to handle a total ball charge of 3245 t at 100% loading with a percentage filling of 295% in both the chambersBall mill optimization Dhaka, Bangladesh 21 March 2010 Introduction MrPeramas Wajananawat Experience: 13 Years (2 y in engineering,11 y in production) Engineering department Kiln and Burning system Siam Cement (Ta Luang) Kiln system, Raw material grinding and Coal grinding Siam Cement (Lampang) Cement grinding and Packing Ball Mill Audit and Optimization PDF Mill (Grinding) Particle 2019年5月2日 What to expect from a cement ball mill inspection Having an independent audit of your cement mill can identify opportunities for productivity improvements, including increasing production or lowering energy consumption It is common to achieve a 510% gain in production by following mill audit recommendationsWhat to expect from a cement ball mill inspection GCP Applied

Design and Optimization of Ball Mill For Clinker Grinding in Cement

The nearby cement plant operates with 20 mins retention time for clinker grinding in the ball mill 70 Ton hold up Power consumption = kW = 75 x Gw x D05 = 75 x 163 x 3805 = 2383 kW (Check its correctness) (13) Grinding energy = 3035 kWh / Ton cement Here, Gw = ball charge, ( Ton ); and D = Effective mill diameter, ( m )2014年12月28日 Process Diagonistics Studies for Cement Mill Optimization The mill is designed to handle a total ball charge of 3245 t at 100% loading with a percentage filling of 295% in both the chambers Both the chambers of the cement mill were charged with 80% of the designed charge,Process Diagonistics Studies for Cement Mill OptimizationBall mill optimization Dhaka, Bangladesh 21 March 2010 1 Introduction MrPeramas Wajananawat Experience: 13 Years (2 y in engineering,11 y in production) Engineering department Kiln and Burning system Siam Cement (Ta Luang) Kiln system, Raw material grinding and Coal grinding Siam Cement (Lampang) Cement grinding and Packing plant Ball Mill Optimization PDF PDF Mill (Grinding) Nature Scribd

Optimization of mill performance by using

As the ball wear rate depends directly on the surface of the media charge, a small variation in power will lead to an important increase of wear rate The risk of underloading or overloading the mill is an additional factor A direct measurement of the ball level in the mill, more accurate than power readings, as well as a control of it, is The ball charge filling ratio and the L/D ratio are influencing the specific power consumption and the throughput simultaneously Furthermore, the absolute fineness of the ball charge and the ball charge grading are important factors for the optimal operation of a optimisation of ball charge cement mill2020年4月18日 R Schnatz “Optimization of continuous ball mills used for finishgrinding of cement by varying the L/D ratio, ball charge filling ratio, ball size and residence time,” International journal of mineral processing, 2004; 74: 5563 C Pilevneli, S Kizgut, I Toroğlu, D Çuhadaroğlu, and E YiğitEffects of Mill Speed and Air Classifier Speed on Performance of

Cement Grinding Optimization PDF Mill (Grinding) Cement

This chemical reaction occurs at high temperature in a rotary kiln, grinding the cement clinker nodules to 100% passing 90 microns in a dry circuit 2 2 Grinding occurs at the beginning and the end of the cement making process Approximately 15 tonnes of raw materials are required to produce 1 tonne ofIt is estimated that mechanical size reduction of rocks, ores, coals, cement, plastics “A Ball Mill Circuit Simulator in ObjectOriented Programming,” available from the Mineral Processing Section, “Optimization of the Ball Charge in a Tumbling Mill,” XVI International Mining Processing Congress, Stockholm (June 1988) Google Size Reduction of Solids Crushing and Grinding EquipmentAn industrial ball mill operating in closedcircuit with hydrocyclones was studied by five sampling surveys The aim of the present study was to optimise operating parameters (ie charge volume, makeup ball size regime, slurry mean residence time, number of hydrocyclones in operation and hydrocyclone’s feed solids content (Sf)) with respect to (PDF) Cement grinding optimisation Alex Jankovic Academia

OPTIMIZING THE CONTROL SYSTEM OF CEMENT MILLING:

Ball Mill Cyclones Weight Feeders Recycling Elevator Sep Feed Mill Feed Sep Return Final Product System Fan Figure 1: Closed circuit grinding system milling system is a delicate task due to the multivariable character of the process, the elevated degree of load disturbances, the different cement types groundPrevious Post Next Post Contents1 Ball charge optimization2 1 How to use the BP21 2 Description of the main indicators used in this BP2101 The residue on 2mm/4mm before partition wall2102 Material filling level and ball charge expansion211 Cement mill specific power 1st compartment 212 Raw mill specific power 1st compartment Ball Ball charge optimization INFINITY FOR CEMENT EQUIPMENT2004年12月10日 During the last decade, semifinishgrinding plants have been used more and more for the energy efficient grinding of highquality cement In 1999, it was found that by decreasing the ball charge filling ratio it was possible to lower the specific energy demand for grinding significantlyOptimization of continuous ball mills used for finishgrinding of

Optimization of the makeup ball charge in a

1992年3月1日 Batch grinding parameters a T 063 min −1 γ 080 α 137 Λ 47 β 62 Φ 0 060 δ 01 a T 112 mm Table 2 Average input values for the fullscale mill and their corresponding interval ranges 2009年11月1日 First results have already shown the extensive potential for determining wellfounded rules for the composition of ball charges in mills for the finish grinding of cement This project was funded Optimisation of the ball charge in mills for cement grinding2020年5月1日 The primary ball charge pattern and the design ball charge pattern that is introduced by KHD Company (Cement ball mill’s manufacture Company) are presented in Table 6 It can be observed in this table that the amount of current ball charge is about 14% less than the amount of design ball charge, so it could reduce the CBM’s efficiencyEnergy and exergy analyses for a cement ball mill of a new

How to Improve Ball Mill Performance 911 Metallurgist

2017年10月25日 Ball Mill Breakage Efficiency Consider a ball mill circuit processing material of a given feed size and at a given throughput rate to a target product size, the latter which once again distinguishes the “fines” from the “coarse” material The production rate of fines or new product size material can be calculated from the circuit feed 2017年1月1日 An increase of over 10% in mill throughput was achieved by removing the ball scats from a single stage SAG mill These scats are non spherical ball fragments resulting from uneven wear of balls (PDF) Performance optimization of an industrial ball mill for 2015年4月1日 1 Introduction Airswept raw meal ball mills introduced by the cement mill manufacturers ® (Smidth, 2002), Polysius ® (Polysius, 2002) and KHD Humboldt Wedag® are the most commonly used onesKHD Humboldt Wedag® manufactured fully airswept raw meal mills which have two compartments used for drying and grinding Optimization of a fully airswept dry grinding cement raw meal ball

Ball Mill Optimization PDF SlideShare

2018年12月17日 The nearby cement plant operates with 20 mins retention time for clinker grinding in the ball mill 70 Ton hold up Power consumption = kW = 75 x Gw x D05 = 75 x 163 x 3805 = 2383 kW (Check its correctness) (13) Grinding energy = 3035 kWh / Ton cement Here, Gw = ball charge, ( Ton ); and D = Effective mill diameter, ( m )Also with low ball charge slurry pool will reduce grinding efficiency Beside lower ball charge will increase P80 of ball mill because of less number of impacts but mean residence time will increase by lower ball charge because of more volume to occupy I think at last in this situation, power consumption will increaseBall Charge and Grinding Efficiency Grinding Classification